- Backstage

Unboxing a piste groomer

Unboxing is an internet trend. You know it: Someone unpacks more or less useful things in front of the camera and reveals what's inside the box. Well, a piste groomer is not delivered in a box. We "unbox" it anyway.

Approximately 100 employees are responsible for preparing the pistes in the Skicircus Saalbach Hinterglemm Leogang Fieberbrunn. Night after night they ensure that the pistes are in pristine condition. The most important machine: the piste groomer. Mostly they are models from the major manufacturers PistenBully or Prinoth. I am present with my camera when a brand new Polar 600 PistenBully is delivered to the Zwölferkogel.

Delivery by truck

At 07:30 we meet at the Hinterglemm lift company's workshop near the 12er KOGEL valley station. Today two new Pistenbullys are delivered. One will join the fleet of vehicles in the Hochalm area, the second will in future ensure pristine pistes on the Zwölferkogel.

Two trucks are required to transport one piste groomer. One truck holds the actual vehicle, the second truck holds the additional parts such as the two chains, blade and tiller. When fully assembled, the snow groomer weighs about 13 tonnes. I always find it very intriguing how unspectacular a snow groomer without chains actually looks. Almost cute with the small wheels. However, the appearance quickly alters, because a few hours later the impressive machine is ready for action in front of me.

Complex transport up the mountain

But first things first. I join the transport to the piste groomer garage above the 12er KOGEL middle station. The convoy halts when we reach the Schwarzachergraben and we drive down the track in our pickup truck with one of the truck drivers to inspect the condition of the road. It soon becomes clear that due to the snow and the ice in places, without snow chains nothing will work. Ten truck tyres are covered with heavy iron snow chains by hand, before we can continue our journey an hour later..

Thanks to the experienced truck drivers, the transport has arrived at its destination without any trouble and the unloading process can start.

The garage for piste groomers including a workshop on the mountain

True: My office cannot keep up with this workplace high above Hinterglemm. Directly above the 12er KOGEL middle station, the staff at the piste groomer garage are on duty all year round. In addition to the "visible" work of preparing the pistes, they are also responsible for various maintenance and repair work on the fleet of vehicles. For example, a service is required every 500 operating hours. A piste groomer is in operation for a total of about 1000 hours during the winter. Tip for readers: When buying a piste groomer, it is the operating hours that count, not the mileage! ;)

Final assembly as teamwork

Our new PistenBully now only has to be assembled. To do so, the "add-on parts" are firstly positioned by crane next to the truck on which the main vehicle is standing. The chains are rolled out and spread out next to each other at exactly the right distances, the blade is placed in front and the tiller behind the chains.

Then comes the most exciting part: The crane is used to lift the 10-tonne vehicle from the truck and place it hovering in centimetre-by-centimetre on the chains. Any mistake here would be really expensive, but it's not the first time the men have done this. After this tricky part has been completed, the chains are clamped onto the wheels and finally bolted together. Then the blade and the tiller are mounted, the hydraulic lines are connected and all nuts and bolts are tightened. After a few hours, the piste groomer with all its components is fully assembled and can wait in the garage for its first mission in the snow.

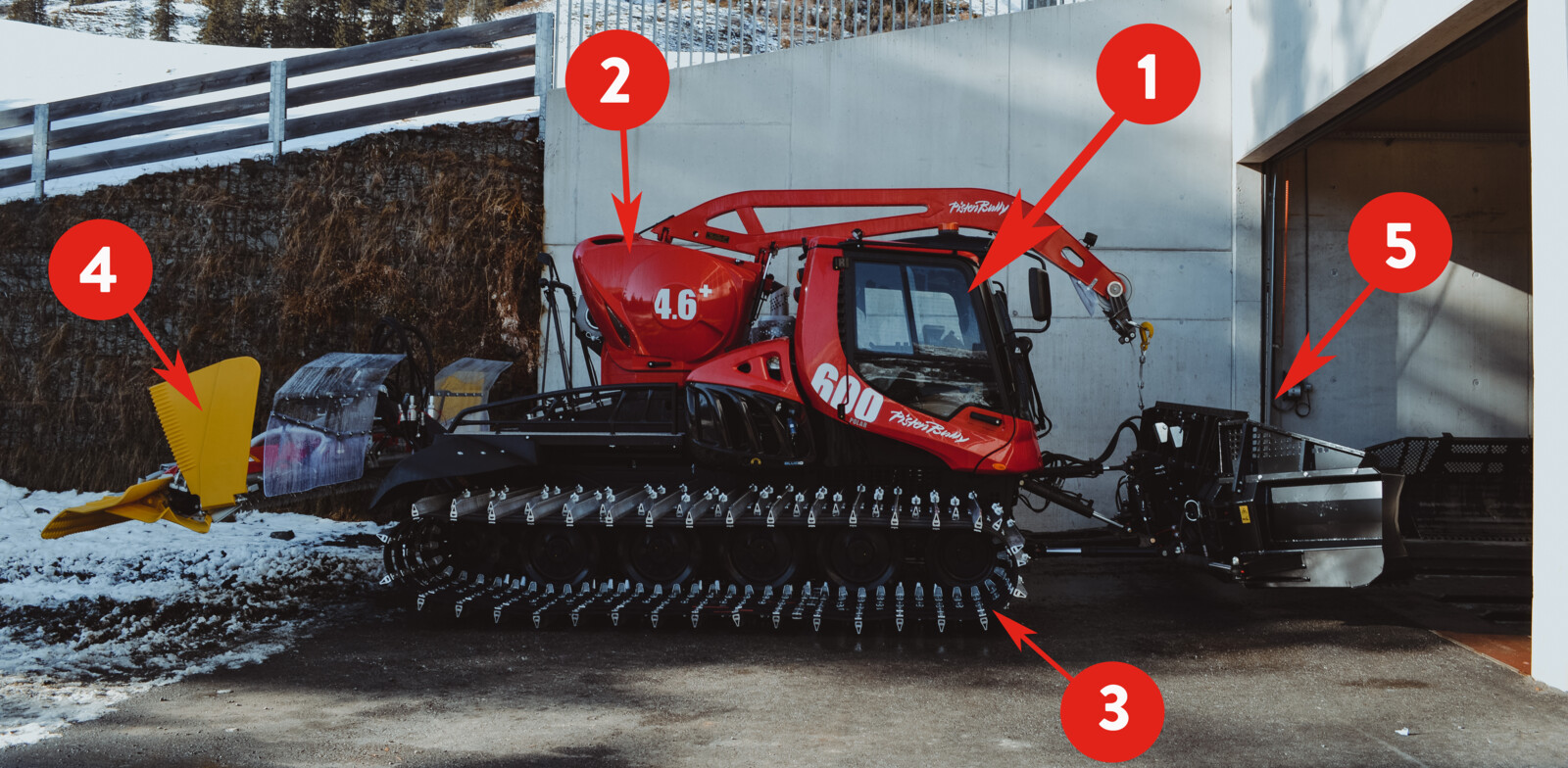

The five elements

The newly delivered Pistenbully in focus. Let's take a look at the five most important aspects of this machine.

- The Vehicle

A 520 HP diesel engine slumbers under the bonnet of the PistenBully 600 Polar. They are also needed when the piste groomer is on the steep World Cup downhill run on the Zwölferkogel at night. In the driver's cab, apart from a great deal of comfort for the piste groomer driver, the most sophisticated technology is provided for. For example, the exact snow height under the piste groomer is determined via GPS, so the driver always knows how much snow he has under the chains and where what is missing or can be removed. The GPS in the piste groomers is also a component of intelligent snow management, because the demand can be determined precisely.

- The winch

More than 1000 metres of steel cable and 4.5 tonnes of tractive force are used in this winch. It is essential on steep slopes, where it secures and supports the piste groomer with its tractive force. The latest generation of winch control systems has already achieved a great deal of automation. For example, the winch recognises in which direction and with which force the snow groomer has to be pulled and thus supports the driver both intuitively and independently. The steel cable is attached to strategically placed anchor points at the edge of the piste.

Important: The long, taut cable poses a danger to life, even if the piste groomer is not visible at all. For this reason, the night-time piste closure from 17:00 hrs onwards must be strictly observed.

- The Chains

The piste groomer's chains, each weighing over one tonne, consist of steel and aluminium struts mounted on natural rubber belts and provide the necessary grip on ice and snow. In addition, due to the large contact surface, they distribute the pressure of the weight of the snow groomer evenly on the slope and "tear" the snow cover. Incidentally, the piste groomer is steered by the fact that the chains run at different speeds.

- The Tiller

Electronically and hydraulically controlled, it provides what skiers then recognise as a freshly groomed piste: The fine rib. The snow "torn open" by the chains is crushed by the tiller and then smoothed by the "finisher lobes" located at the very back and provided with the characteristic ribs. The Plexiglas plates between the vehicle and the tiller "catch" the lumps of snow and ice thrown up by the chains and feed them to the tiller, as they would otherwise fly over the tiller.

- The Blade

The unavoidable piles that appear after a long day of skiing, especially on steeper parts of a slope, are no problem for the blade. The hydraulically controlled plough makes short work of piles and mounds and levels the slope perfectly. In addition, the caterpillar drivers use the blade to push snow in places where GPS indicates that the snow cover is too low.

Piste groomers for summer use

The lift companies are also responsible for the summer landscape maintenance of the company's own piste areas. If the areas were not managed and maintained by mowing, etc., the meadows would quickly become overgrown. This would make it more difficult to prepare the pistes in winter because the ground would become increasingly uneven. Incidentally, the grass cuttings would remain on the meadows, thus ensuring perfect green manure.

For the special tasks in summer, the piste groomers are simply converted. So you get summer chains, which are considerably narrower and only made of rubber. Instead of the tiller for preparing the pistes, a beater mulcher is fitted. This way the steep slopes can be perfectly prepared.