- Backstage

24 hours on the mountain - The Night Shift

The time has come - the last skiers are in the valley and it's wonderfully quiet on the mountain. The piste closure comes into force at 17:00. When some people finish their day's skiing, others start their working day. Only men work on the slopes in the Skicircus in the evening.

The night shift as a "snowmaker" and piste groomer driver is still a very rarely chosen career field for women, although women are generally being seen more and more often as employees on the mountain. Who knows what will happen in the next few years - maybe I'll soon be able to write a story about the first female piste groomer driver in the Glemmtal valley!? In any case, today the focus is on the men who make sure the pistes are perfect at night while skiers rest their tired legs. While Helli, who gave me an insight into the rescue service during the first story day shift, "snows" at night, Manfred fine-tunes the Funslopes and prepares the slopes in the Hochalm area together with a total of nine other snow groomer drivers. Let's go!

Snowmaking on the slopes in the Skicircus

The reservoirs, which serve as retention basins and collect water in summer, provide additional snow on the mountain and perfect conditions on the slopes in winter. The ponds are embedded in the landscape under strict environmental protection regulations and thus become a new habitat for insects, dragonflies, frogs and many more. In the warmer summer months, they also serve as a source of water for wild animals. Easy access to water is just as important for bees as it is for foxes, deer, ducks and birds. In addition, compensatory measures such as reforestation and biotope construction are carried out - for example, the beautiful Himmelsteich pond was created next to the Rosswald reservoir. The ponds are popular recreational areas for locals and guests in both summer and winter.

The water used for snowmaking is made up exclusively of spring, rain and meltwater. As the snow melts and evaporates, all of the water is returned to nature. The water basins created compensate for these energy consumption peaks with the help of the pumps in the pumping stations and also serve as flood protection in summer. The energy required for the additional snowmaking is generated entirely from renewable energy sources such as hydropower, photovoltaics and biomass. If you would like to read more on this topic, you can find detailed information on the environmental protection measures implemented in the ski area here.

From theory to practice

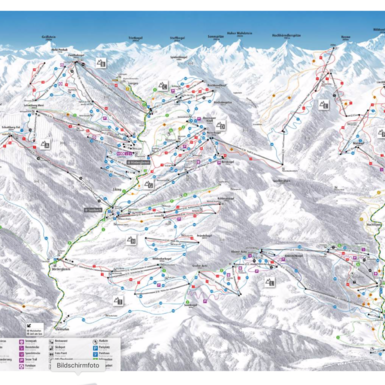

The Skicircus Saalbach Hinterglemm Leogang Fieberbrunn is one of the biggest employers in the region. This requires well thought-out operating concepts. And their success proves them right - at the latest when you stand on the perfect piste early in the morning, you realise what work was necessary in the background overnight.

"Schneiber" - profession & vocation

Helli has been employed at the lift during the winter months for over 30 years and works as a rescue worker during the day or as a "Schneiber" at night, depending on what is needed. This is what we colloquially call the employees who are responsible for the smooth running of the night-time snowmaking. ("Es schneib" = "It's snowing" in the Pinzgau dialect. And that's why a snowmaking technician is simply called "Schneiber").

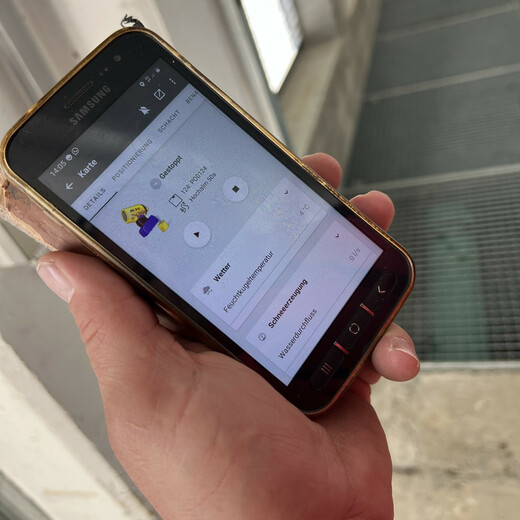

The night shift starts at 19:00. There is no fixed duty rota, according to the motto: "When we can snow, we let it snow." This is the case from around minus three degrees centigrade and below. The team (there are always two of them on snow duty) can access the snow machines from home via the specially developed mobile app and get an overview of the temperatures. Together with the operations manager on duty, they then decide whether, when and how to start making snow. And, as we already know from the day shift, the night shift begins with a control run.

All snow machines in position!

All snow machines are positioned, covered if necessary and started. Over the next 12 hours, the cannons are precisely adjusted, set and checked at short intervals. In addition to the visual inspection, the app and the computer programme in the pumping station office are used to display any error messages and anomalies with pinpoint accuracy.

The automated snow depth measurement system, which is built into the modern snow groomers, shows exactly where and when how much snow needs to be produced in order to achieve perfect results in coordination with the snow groomer driver. Precise snowmaking is possible thanks to the exact measurements - so there is no unnecessary consumption of water or energy.

In general, only a certain amount of water may be used. In many winters, this is not fully utilised. Precise planning and realisation make it possible to conserve resources.

The final round begins at 06:00 - all snow machines are switched off or covered up again depending on their position. This is followed by a meeting with the operations manager on duty before it's "End of service!" at 07:00.

On a day when it snows or when the slopes are covered with snow, it is up to the snow groomer drivers to spread the snow on the slopes and roll a perfect surface. There isn't much time - after all, the first lifts will open again in less than an hour. The perfect pistes therefore also require precise time management.

On nights when it doesn't snow and when there is no snowmaking, the funslopes and pistes are groomed in the evening. Just like today.

Out and about at night on the Funslopes and pistes

It's 4.00 pm and the Hochalm snow groomer team starts work. They start with a briefing followed by a check of the machines. The men work closely together and in close consultation - everyone knows what to do when they get into their snow groomer shortly after 5.00 pm and head off to the area they have been assigned to.

Maximum flexibility is required

Deputy snow groomer manager Mark, who has been working for the cable car company since 1997, lets me sit in on the meeting this time - and reveals exciting facts about the team, the workflow, the machines and the common goal: the perfect piste!

- The team's maximum flexibility ensures perfect timing - depending on the weather, the pistes are groomed in the evening (or in the morning if it snows).

- The snow groomers are different models from the manufacturers Kässbohrer and Prinoth and are each manned by a driver.

- Each snow groomer driver has his own fixed area. In the end, however, they work together until all slopes are in perfect condition.

- The machines are overhauled and maintained in the company's own garage. Any damage can be repaired in the shortest possible time.

- The snow groomers generally remain in operation for 10 to 12 years - depending on their condition - and then have 10,000 to 12,000 operating hours on the counter.

- A normal car driving licence is required to work as a snow groomer operator, and an in-house driving licence is required.

- In addition to grooming, the tasks of a snow groomer operator include machine care and maintenance. Lubrication, washing, visual inspections and oil level checks are carried out here.

- The goal of the day? THE PERFECT FINISH! That's what they call it, I've been told.

I'm very interested in what makes a good snow groomer driver. The team is unanimous: it's all about talent and feeling. Some get the hang of it very quickly, others simply need a little more practice to prepare the perfect run.

Kevin, the new kid on the block, chose this job because of his keen interest in machines. "It's more challenging than I thought - but super cool!" he says.

I would like to know what has changed in the last few years since Mark has been travelling around the ski area at night. He says: "The modern machines including snow depth measurement, the attractive and customised working hours and the in-house garage are probably the most significant changes. These things have simplified many things and perfected the process."

And then we have to get going - after all, the piste doesn't groom itself.

I'm travelling with Manfred today - in addition to grooming the piste, he's also responsible for the funslopes in the area assigned to him. A few minutes after we set off together, I'm already inside: in "his" Pistenbully Level Red 600 Polar with 520 hp.

Manfred can also look back on a long time with the company. He started in 1991 and was stationed at the Hochalm T-bar lift back then. He has now been a grommer for 30 seasons. In addition to grooming the piste, he also builds the funslopes in the Hochalm area. Depending on the snow conditions, he faces different challenges every day. As we head towards the summit at just under 13 km/h, it starts to rain.

Which type of snow is the best in terms of preparation?

Manfred explains: "Soft snow and subsequent rain make grooming a challenge. The heavy snow, which later on when it gets colder, is difficult to distribute evenly. It's best when it's cold and there's fresh new snow."

We are on a pure natural snow piste without any piste correction. This is another factor that plays a role in grooming. In order to be able to "push" the snow evenly, six of the seven machines in use in this area have a winch. As the sun appears again on the horizon, I realise what everyone is raving about - the peace and quiet and the view are truly unique! Once at the top, Manfred attaches the piste device to the anchor point on the winch. The rope is 1,400 metres long and pulls 4.5 tonnes.

Using the latest technology, he can see at a glance how thick the layer of snow is below us with the in-built snow depth gauge. One metre is the ideal guide value. The technology is a great support, but it doesn't replace a feel for the piste. And that, in turn, comes with experience and passion. After Manfred has prepared the entire area, we ski to the summit again and he unhooks the winch. Now it's time for the funslopes!

The experienced rider has a free hand in the design of the funslopes. Depending on the terrain and the condition of the snow, he builds the bends and hills. After construction, the slopes are inspected and approved by the operations managers. Once built, the slopes are refreshed daily and prepared for the next day. Kids in particular love these areas, which lead through almost a kilometre of varied terrain back to the piste. Perfect for the little ones!

Manfred then takes me to his colleague Andy, who prepares the lower section of the Hochalm. He takes me back down into the valley. I am infected by the joy and passion for the perfect piste. When you see the end result, you can hardly wait for the lifts to open the next morning.

Let me resume my "24 hours on the mountain experience"

All the people I've met in the last 24 hours share a passion for the job and working together on the big picture. It's all about the overall skiing experience - for guests from all over the world. It doesn't matter whether you're an early bird getting on the gondola early in the morning and enjoying the slopes or whether you can rely on a team that provides routine, calm and professional support in an emergency, even in exceptional situations. In any case, you are in good hands, I can personally summarise!